CEMENT

What is cement ? Definition of cement.

Cement ,chemical substance that’s mixed with sand, gravel, and water to form concrete, which provides strength and durability to structures. ((The term cement, meanwhile, drives from the Latin word caementum, which meant stone chippings such as were used in Roman mortar—not the binding material itself.))

In simple word, Cement is a powder consisting of mixture of minerals that becomes hard when water is added. It is often mixed with sand and small stones to make concrete.

its manufacture from raw materials . Cement is a mixture of oxides and silicate compounds of many metals like calcium, aluminium etc.Cement is important building material.

RAW MATERIALS

It is produced by combining a material rich in lime, Cao with other material such as clay which contains silica, Sio2 along with Al2O3, Fe2O3, MgO and SO3.

Extraction;

The raw materials used in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestone, slate and some shale, with the help of blasting when necessary. Some deposits are mined by underground methods.

The essential components of cement

• Chemically, cement is a mixture of calcium silicates and small amounts of calcium aluminates that react with water and cause the cement to set.

• The mix is completed with the addition of 5% gypsum to help retard the setting time of the cement.

Cement Manufacturing process

Cement manufacturing is a complex process in which crushing and grinding the raw materials, blending the materials in the correct proportions, burning the prepared mix in a klin and grinding the burned product, known as clinker..

Types Of Cement:

1.Ordinary Portland Cement : This is the most commonly used cement in construction projects worldwide.

2.Portland Pozzolana Cement: PPC is a type of blended cement comprising Portland clinker, pozzolana particles and gypsum in certain specific proportions.

3.Rapid Hardening cement : Rapid-hardening cement is a type of hydraulic cement that’s specially designed to gain strength quickly

4. Extra Rapid Hardening Cement:

5. Quick Setting Cement: Quick-setting cement is a type of hydraulic cement that’s designed to set and harden quickly

6 .Low Heat Cement: Low heat cement is a type of hydraulic cement that’s specially designed to produce less heat during the hydration process

7. Sulphate Resisting Cement:

8. Blast Furnace Slag Cement

9. High Alumina Cement

10. White cement: White Cement as its name suggests has a high degree of whiteness. White cement is used primarily for decorative purposes, such as in the construction of architectural elements, precast concrete products, and terrazzo flooring

11. Coloured Cement: Coloured cement, also known as pigmented cement, is a type of hydraulic cement that’s mixed with pigments (5 to 10% pigment) to achieve a range of colours.

12. Air entraining Cement : Air entraining cement is a hydraulic cement that contains air-entraining agents, such as resins, glues and sodium salts, to create microscopic air bubbles within the concrete mix.

13. Expansive cement

14 .Hydrographic cement: Hydrographic cement is a specialised type of Portland cement that’s designed to set and harden underwater

15. Portland Limestone cement : Portland limestone cement (PLC) is a type of blended cement that’s made by inter-grinding Portland cement clinker and 5 to 15% limestone.

DIFFERENT GRADE OF CEMENT::

33 Grade Cement:

33 grade cement is commonly used for general construction work and plastering

43 grade Cement :

cement is the most commonly used grade of cement in India. It has a compressive strength of 43 N/mm² after 28 days of curing. It’s suitable for use in construction projects where moderate to high strength is required, such as plain concrete or plastering works

53 Grade Cement;

53 grade cement is the highest grade of cement available in India. It has a compressive strength of 53 N/mm² after 28 days of curing. This type of cement is suitable for use in construction projects where high strength is required, such as in the construction of high-rise buildings, dams, and heavy-duty industrial structures.

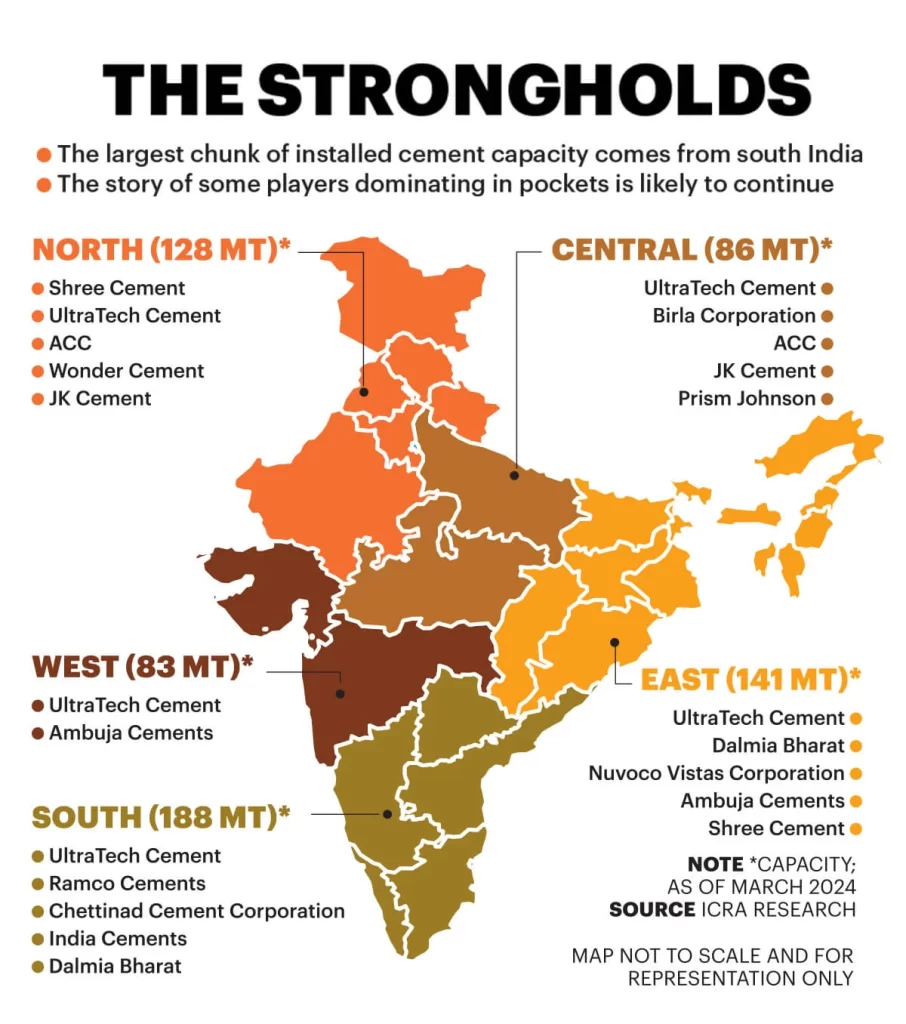

Top ten cement company in india

- UltraTech Cement Ltd. …

- Ambuja Cements Ltd. …

- ACC Limited. …

- Shree Cement Ltd. …

- Dalmia Bharat Ltd. …

- Ramco Cements Ltd. …

- Grasim Industries, Inc. …

- JK Cеmеnt Limitеd.

- NUvoco …

- Jindal panther….

So on…..

There is a sharp focus on our supply chain management, specifically logistics operations. We must continue to optimise costs and ensure improved customer response time ”

K.C. JHANWAR

Managing Director

Ultratech Cement

Read on next